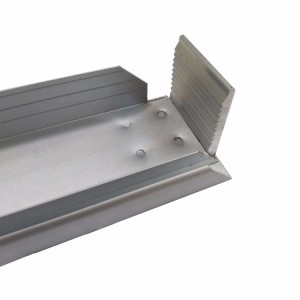

Xidhiidhiyaha unugga ribbon ee silig baska baska

Sharaxaada

Hantida Makaanikada ee Siliga Qoraxda:

1. Dheeraynta: E-Soft>=20% U-Soft>=15%

2. Xoog xajin:>=170MPa

3. Kambar dhinaca: L<=7mm/1000mm

4. Meesha dhalaalka daasadda lagu iibiyo: 180 ~ 230 ° C

Iska caabinta Korontada ee Copper:

TU1<=0.0618 Ω·mm2/m; T2<=0.01724 Ω·mm2/m

Copper Core of TU1 Off-Cu ama ETP1:

1. Naxaasta Naxaasta>=99.97%, Ogsajiinta<=10ppm

2. Iska caabin: ρ20<=0.017241 Ω·mm2/m

Iska caabinta Korontada ee Ribbon:

(2.1~2.5)X10-2 Ω·mm2/m

Dhumucda Dahaaran:

1) Gacmaha iibinta: 0.02-0.03mm dhinac kasta

2) Mashiinka-Alxanka: 0.01-0.02mm dhinac kasta

Halabuurka Walxaha Dahaaran:

1) Alaabooyinka taxanaha ah ee rasaasta:

A.Sn 60%, Pb 40%

B.Sn 63%, Pb 37%

C.Sn 62%, Pb 36%, Ag 2%

D. Sn 60%, Pb 39.5%, Ag 0.5%

2) Alaabta taxanaha ah ee bilaa rasaasta:

A. Sn 96.5%, Ag 3.5%(Bi)

B. Sn 97%, Ag 3% iyo wixii la mid ah

Ku saabsan Tabbing Ribbon & Bar Ribbon baska

ribbon PV wuxuu ka kooban yahay Copper iyo Alloys dahaar ah, waxaana loo qaybiyaa Tabbing Ribbon iyo ribbon baska.

1. Ribbon taabsi

Tabbing Ribbon waxay caadi ahaan isku xidhaa dhinacyada togan iyo kuwa taban ee unugyada taxanaha ah.

2. Bar baska Ribbon

Barka baska Ribbon wuxuu xooga saaraa xadhkaha gacanta ee isku xidha sanduuqa iyo kanaalada hadda korantada.

Ku saabsan Dahaarka Dahaarka:

Nooca dahaarka waxaa lagu go'aamiyaa naqshadeynta iyo baahida macaamiisha. Waxay u qaybsantaa dahaarka sunta rasaasta ah iyo kuwa dhintay ee xorta ah. Waqtigan xaadirka ah nooca dahaarka rasaasta si weyn ayaa loo isticmaalaa, laakiin mustaqbalka waxa loo soo saari doonaa nooca dahaadhka rasaasta ka madax banaan.

tilmaamo

| SIZE(mm) | dhumucdiisuna (mm) | WAXYAABAHA NAxaasta ah | Dulqaadka | ||

| WXT | Saldhigga Copper | Jaakad dhinac kasta | Ballaca | Dhumucda | |

| 0.6x0.12 | 0.0500 | 0.0150 | TU1 | +/-0.05 | +/-0.015 |

| 0.8x0.08 | 0.0500 | 0.0150 | TU1 | ||

| 0.8x0.10 | 0.0500 | 0.0250 | TU1 | ||

| 1.0x0.08 | 0.0500 | 0.0150 | TU1 | +/-0.05 | +/-0.015 |

| 1.0x0.10 | 0.0500 | 0.0250 | TU1 | ||

| 1.5x0.15 | 0.1000 | 0.0250 | TU1 | +/-0.05 | +/-0.015 |

| 1.5x0.20 | 0.1500 | 0.0250 | TU1 | ||

| 1.6x0.15 | 0.1000 | 0.0250 | TU1 | +/-0.05 | +/-0.015 |

| 1.6x0.18 | 0.1250 | 0.0275 | TU1 | ||

| 1.6x0.20 | 0.1500 | 0.0250 | TU1 | ||

| 1.8x0.15 | 0.1000 | 0.0250 | TU1 | +/-0.05 | +/-0.015 |

| 1.8x0.16 | 0.1100 | 0.0250 | TU1 | ||

| 1.8x0.18 | 0.1250 | 0.0275 | TU1 | ||

| 1.8x0.20 | 0.1500 | 0.0250 | TU1 | ||

| 2.0x0.13 | 0.0800 | 0.0250 | TU1 | +/-0.05 | +/-0.015 |

| 2.0x0.15 | 0.1000 | 0.0250 | TU1 | ||

| 2.0x0.16 | 0.1100 | 0.0250 | TU1 | ||

| 2.0x0.18 | 0.1250 | 0.0275 | TU1 | ||

| 2.0x0.20 | 0.1500 | 0.0250 | TU1 | ||

Habka Tignoolajiyada

1, Samaynta fiilooyinka wareegsan ee fiilooyinka siman iyada oo loo marayo sawiridda iyo duubista

2,Daawaynta kulaylka

3, Masaafad kul-kulul

4,Spooling sax ah

Saldhigga Copper waa xariijimaha naxaasta ah ee xorta ah ee ogsijiinta oo ay ku rakiban yihiin qalab duuban oo sax ah oo laga keenay Jarmalka

Waa mid jilicsan oo aan lahayn cidhifyo, qallafsanaanta jilicsan waxaa lagu hagaajin karaa shuruudaha macaamiisha.

Iyada oo la adeegsanayo tikniyoolajiyadda qaacida ah, jaakad alloy-ga daasadda ah waxaa soo saara qalabyo-kuleyl-dhuuqista xirfadeed oo laga keeno Japan. Coat suface waa dhalaalaya oo xitaa, waxay leedahay waxqabad la heli karo iyo antioxidant xoog leh oo ka caawiya hagaajinta dhalidda alxanka. Dhumucdiisuna waxaa lagu hagaajin karaa baahida macaamiisha.

Ribbons-ka waxaa loo samayn karaa si loo dalbado iyadoo loo eegayo moduleka qoraxda iyo cabbirkiisa

Bandhiga Alaabta